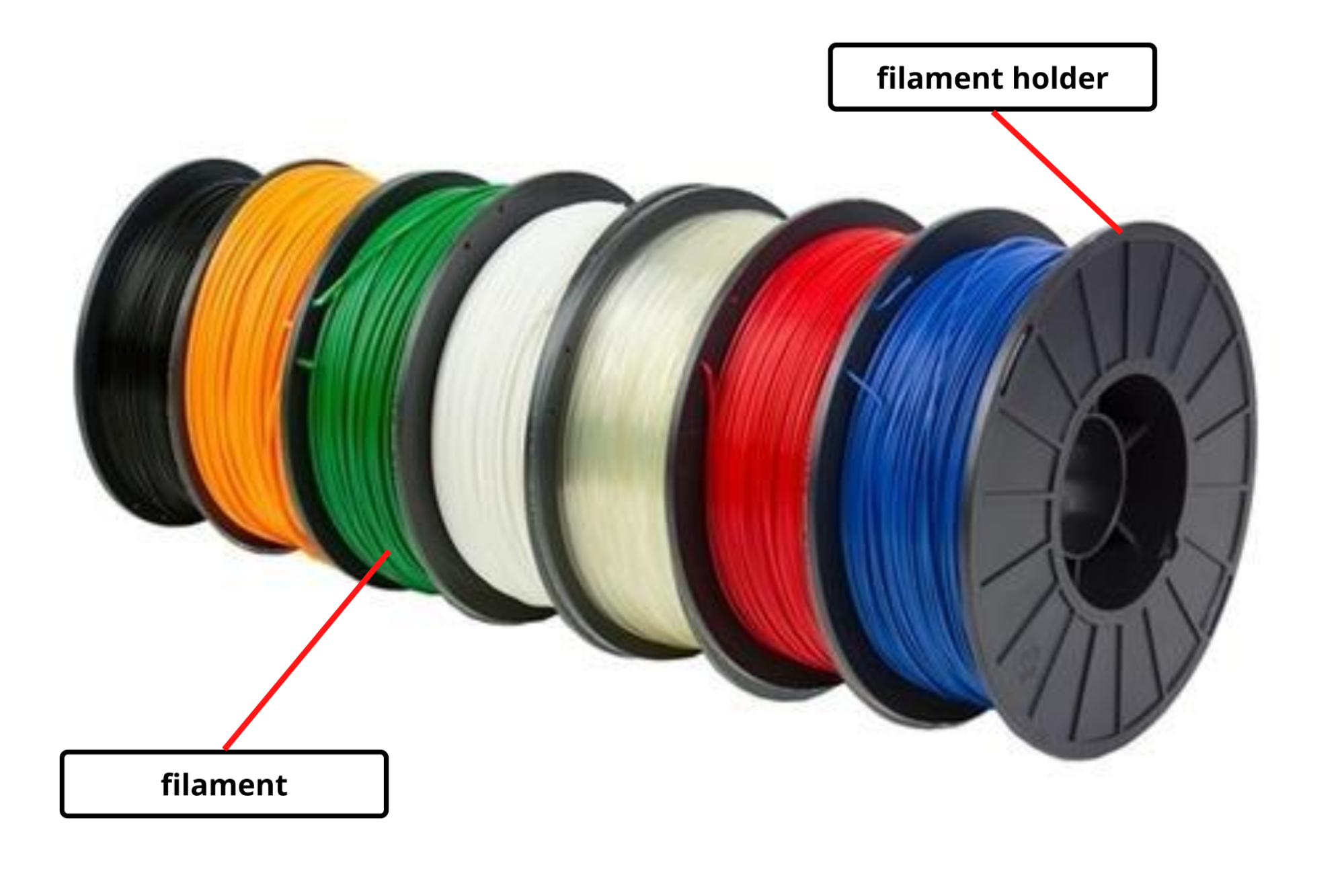

Filament is an important requirement for 3D printing. Filaments used in 3D printing are thermoplastics, which are plastics that melt rather than burn when heated, can be shaped and moulded, and solidify when cooled.

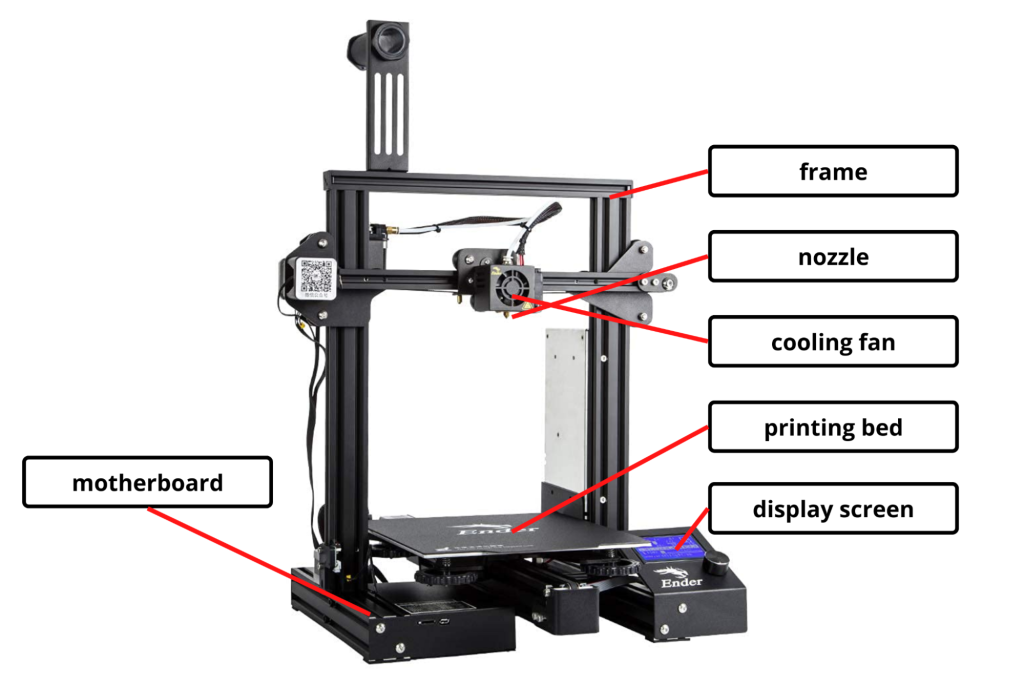

The filament is fed into a heating chamber in the printer’s extruder assembly, where it is heated to its melting point and then extruded (squirted) through a metal nozzle as the extruder assembly moves, tracing a path programmed into a 3D object file to create, layer by layer, the printed object.

The two most common filaments are standard diameters of 2.85 mm and 1.75 mm. They usually look like wire and are fitted such that they can be fed to the printer while in use.

How to use

Open the loose end of the filament, and cut a very small part to make sure that the end is plain and angled. Then, push the filament straightly into the hole that takes it towards the nozzle. Once the filament reaches the nozzle, it’ll start oozing out a bit. Pull off the extra part of the filament and done, the filament is now loaded into the printer.

Safety Measures to follow

1. Keep the filament away from hot or humid environments.

2. Make sure that the filament is not twisted to ensure smooth flow.

Important Links

Different types of filaments –

https://www.youtube.com/watch?v=qajTuTQUPsQ

How to load filament in a 3D printer –

https://www.youtube.com/watch?v=b2eiHFkSb0E